aNewDomain.net — Home Depot started selling MakerBot Replicator Desktop 3D Printers on July 14, 2014. The 3D printers are available in select stores in the United States. That announcement may not raise many eyebrows in the business world, but it should.

For the next 10 years or so, as the technology and the industry mature, affordable desktop 3D printing is going to change the way we do just about everything. And as happens with any disruptive technology, there will be winners and there will be losers. The trick will be to recognize which is which — and not just next year, but 20 years from now.

Home Depot

Photo Credit: Business Wire

Home Depot is collaborating with MakerBot, a subsidiary of Stratasys Ltd., in this joint venture. The 12 select Home Depot stores are located in California, Illinois, and New York, but it stands to reason that the number of outlets will grow over time.

MakerBot’s CEO Bre Pettis spoke with enthusiasm about the deal in a press release:

We are thrilled to partner with The Home Depot to help bring MakerBot 3D printing technology to The Home Depot customers. Imagine a world where you can 3D print replacement parts and use 3D printing as an integral part of design and building work. Every day we see the magic of 3D printing becoming a reality with our customers; now The Home Depot can also see that magic. We can’t wait to see what The Home Depot customers make with our products.”

While MakerBot is certainly a prominent player in the 3D printer industry, it’s not the only one. Other companies, such as 3D Systems, compete in this burgeoning market and hold the same level of excitement. 3D Systems CEO Avi Reichental has been quoted to say when talking about the future of 3D printing:

The question we should be asking is what room in your house will your 3D printer be.”

The Motley Fool has been covering the 3D printing industry in great detail as a long-term investment theme. In the TMFPostOfTheDay Blog, under “Mega Themes Investing — 3D Printing,” you can find an in-depth review of the major companies in this industry.

Beyond 3D Printers

But there is something to consider beyond the actual 3D printer manufacturers themselves. The business model for 3D printers is similar to the model for inkjet printers and ink cartridges, blades and razors or coffee makers and individual coffee packets. The revenue stream comes from replacing the materials required to make the particular hardware work.

MakerBot and 3D Systems want to be your supplier of 3D printer materials, but they’re not the only companies in the market. Startup businesses like MadeSolid are researching and developing advanced materials to use in your 3D printer, instead of what is supplied by the manufacturer. Other startups are bound to get into the market as the industry grows and the potential revenue becomes too enticing to ignore.

While the comparison to the blades and razor business model holds up in many ways, 3D printing has one big difference that should concern the printer manufacturers and their stakeholders. Basically, the fight over who supplies the blade for your razor is based on the fact that blades are commodities. For the consumer, the supplier of the blade is not really important — cost is typically the deciding factor.

For 3D printer manufacturers, however, the fight is over which company supplies the best material for the job at hand. This is not a commodity at all. The chemical materials and methods used in the printing process are still being tweaked and refined. Competition for customers will not lie with the hardware exclusively, but also with the materials that go into the hardware.

Beyond the Material and the Hardware

There is another aspect to consider in this developing industry of 3D desktop printers. Beyond the hardware and the printing materials lies pattern design. Just like your inkjet printer, a 3D printer needs software to tell it what to print. Those designs and patterns have to come from somewhere.

A dentist can scan your tooth to help create your crown, but how do you print a dragon figurine unless you have the design? I don’t know about you, but my creative skills as a sculptor in a CAD application are severely limited.

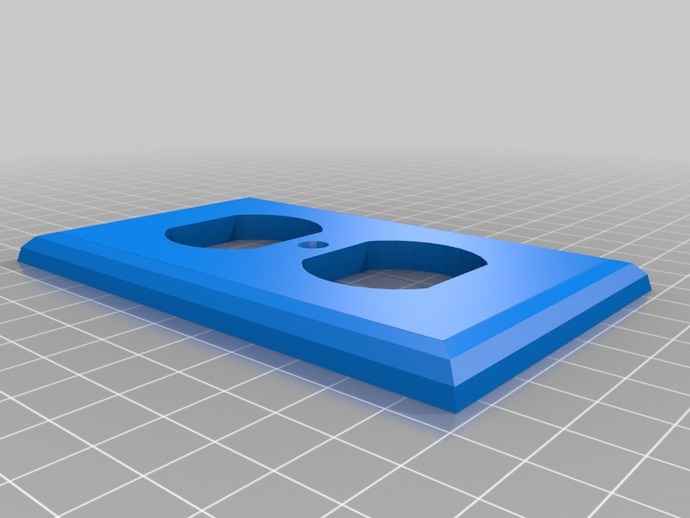

Image and design by William A. Adams

When it comes to MakerBot, the answer is the website Thingiverse. On Thingiverse you can find a hundreds of designs for everything from the aforementioned dragon to something as simple as an electrical outlet cover. The designs are free and licensed for personal use. Thingiverse follows the culture open-source software, where a community of enthusiasts collaborate on projects for the simple joy of doing it.

Now, imagine if you are the manufacturer of electrical outlet covers — how do you compete with this new model?

Bottom Line

If you’re trying to make sense of the disruption caused by affordable desktop 3D printers, you have to follow the ripples. Besides the obvious competition between the hardware manufacturers, you also have to consider who will supply the materials.

And beyond that, you have to consider who will design the things that get printed. A thriving culture of hobbyists designing doo-dads or wall outlet plates is fun for the consumer, but barely scratches the commercial surface. Are we going to see a retooling of the engineering design industry? Will manufacturers produce their plastic parts with 3D printers rather than buying them?

And going even deeper, consider those manufacturers of small plastic parts. Will the market for dragon figurines and electrical outlet plates shrink because we print our own? Should manufacturers in China, where many inexpensive plastic parts are made, be worried? What about the shippers of those Chinese products, should they be looking for additional revenue streams? What about retailers like Dollar Tree — will there still be a market for molded plastic do-dads in 10 years? Will Home Depot need to carry large inventories of outlet plates if building contractors can just print what they need when they need it?

The disruptive wave created by 3D printer technology is only beginning. Many companies and many lives are going to be impacted by this fundamental change in how things get made. While they may not know the specifics yet, informed people should be aware that changes are coming and that opportunities will reveal themselves. Desktop 3D printing is going be a key theme for the next decade, but the impact is also going to permanently change the manufacturing landscape.

We will all need to follow the story closely if we want to take advantage of the ripple effect.

For aNewDomain.net, I’m Mark W. Kaelin.

Senior Editor Mark W. Kaelin has been writing and editing stories about the information technology industry, gadgets, finance, accounting, and tech-life for more than 25 years. Most recently, he was a senior editor for TechRepublic, a division of CBS Interactive, Inc. Follow him @MarkWKaelin and find him on Google + here.

Great perspective story

Agreed!

Biological 3-D printing is also an exciting topic — lots of links at:

http://lifesciences.ieee.org/articles/feature-articles/332-printing-body-parts-a-sampling-of-progress-in-biological-3d-printing

Great job! Love the perspective on the topic.

Great analysis

[…] 3D Printers Will Disrupt Our Lives in Ways We Can’t Fully Understand […]