aNewDomain.net — Print isn’t dead by a long shot. It certainly isn’t in the industrial and banner printing market. Basically anything that you use wide-format printers for will be thriving for many years to come. And printers who want to invest in new machines will be happy to know they will be able to print on more media with UV LED technology than with traditional mercury vapor lamps, and how eco-friendly technology brings in more business.

Ranging from 365 to 405 nm, UV LED lamps are increasingly replacing power-hungry, toxic ozone-spreading mercury vapor lamps in wide-format UV curing printers. The evolution may gain momentum in 2014 when Europe is rumored to possibly ban mercury vapor lamps altogether. But the “green” aura around LED lamps may not be the reason why savvy printers opt for a UV LED curing press.

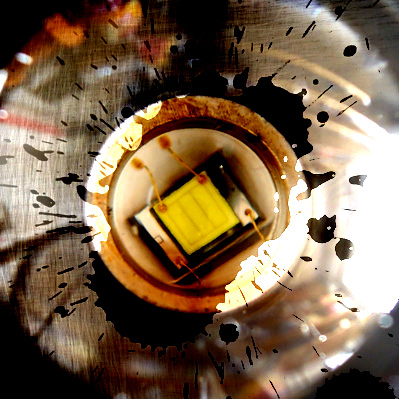

Image credit: Erik Vlietinck

In a village in Zeeland, the Netherlands, I found the first European printer with a wide-format UV LED curing inkjet. JMC Signmakers — originally a signage company — has been running an EFI VUTEk GS3250LX for close to a year now. The printer uses Phoseon lamps and EFI’s true greyscale print head technology.

JMC Signmakers has customers all across the Netherlands. In an interview, the company’s CEO said that even before the printer got installed, his customers jumped on the idea of “being green” when ordering billboards or glossy displays for their cosmetics shops.

But what really got JMC Signmakers’ business going was the speed and extended range of printing services this UV LED inkjet allowed it to provide.

The relative cool temperatures of UV LED curing lamps during operation allows printers to use a larger range of heat-sensitive media. This enables printers like JMC Signmakers to address a much broader market than they ever could before. Traditionally, wide format inkjets are used to print billboards and store ad displays.

With their UV LED printer, JMC Signmakers are now printing directly on exotic materials like bubble wrap. Apparently, UV LED technology also lets the company print more efficiently (and faster) on static charged polypropylene than traditional UV printers because heat has a negative effect on the static charge of the material.

Already JMC Signmakers are seeing cost savings as it has been able to print on cheaper types of cardboard and paper. Cheaper media absorbs more moisture than high-quality paper products. Consequently, the heat of mercury lamps made the cheap stuff warp. The media curled up so badly that it would stick to the print heads creating a host of problems.

CEO Cees Bolijn found the output quality of the EFI VUTEk GS3250LX to be close to screen print. It is clear that UV screen printing and even UV flexographic printing stands to benefit hugely from UV LED curing. Just imagine the power bill decreasing by 70 to 80 percent, as JMC Signmakers has experienced.

If you can print on bubble wrap, what’s going to keep you from printing on packaging plastics directly? Think pre-packed food preparations for supermarkets. These applications would require working closely with ink formulators to ensure food-safety regulations are met.